Introduction to Demand Flow Technology

Demand Flow Technology (DFT) represents a paradigm shift in the way manufacturing and production processes are managed. This approach focuses on synchronizing production with actual customer demand rather than relying on forecasts. By utilizing principles derived from lean manufacturing, DFT aims to reduce waste, improve efficiency, and enhance the overall responsiveness of the manufacturing process.

The core idea is to establish a seamless flow of materials and information that aligns with real-time demand, ensuring that products are produced only as they are needed. This methodology not only optimizes resources but also helps in creating a more agile production environment capable of quickly adapting to market changes.

Understanding the Principles of Demand Flow Management

At the heart of Demand Flow Technology is the principle of demand-driven production, which emphasizes producing goods based on actual customer needs rather than historical data or forecasts. This approach revolves around several key principles:

- Flow over Batch: DFT encourages continuous production flows instead of batch processing, reducing lead times and inventory levels.

- Pull Systems: In this setup, production is triggered by actual consumption rather than pushed by forecasts, aligning production closely with market demand.

- Value Stream Mapping: This technique helps visualize and optimize the flow of materials and information, identifying waste and areas for improvement.

By adhering to these principles, organizations can create a more efficient and responsive manufacturing environment that meets customer expectations while minimizing waste.

The Evolution of Demand Flow Systems

The concept of Demand Flow Technology has evolved significantly over the years. Originating from traditional lean manufacturing practices, it has integrated various methodologies to enhance production efficiency. Early models focused primarily on Just-in-Time (JIT) production, emphasizing minimal inventory levels and timely deliveries. As industries began to recognize the benefits of a more responsive production model, Demand Flow Systems emerged, incorporating advanced analytics and real-time data to optimize manufacturing processes. This evolution reflects a broader trend toward embracing agile manufacturing practices, which prioritize flexibility and responsiveness in production environments.

Key Components of Demand Flow Manufacturing

Successful implementation of Demand Flow Technology hinges on several key components that work together to create a streamlined manufacturing process:

- Real-Time Data: Leveraging data analytics to monitor production metrics, customer demand, and inventory levels is crucial. This enables manufacturers to make informed decisions quickly.

- Flexible Production Systems: Equipment and processes must be adaptable to change, allowing for rapid shifts in production based on real-time demand.

- Collaboration Across Departments: Effective communication between sales, production, and supply chain teams is essential to ensure alignment on customer demand and production schedules.

- Technology Integration: Utilizing software and tools designed for demand flow management can significantly enhance the efficiency of operations.

By focusing on these components, manufacturers can create a robust framework for implementing Demand Flow Technology successfully.

Benefits of Implementing Demand Flow Technology

Implementing Demand Flow Technology offers numerous benefits that can significantly impact a company’s bottom line. Here are some of the key advantages:

- Increased Production Efficiency: By aligning production with actual demand, organizations can reduce excess inventory and streamline operations.

- Reduced Lead Times: Demand Flow Systems enable quicker response times to market changes, allowing manufacturers to meet customer needs promptly.

- Cost Savings: With lower inventory levels and more efficient processes, companies can significantly reduce operational costs.

- Enhanced Customer Satisfaction: By producing what is needed when it’s needed, organizations can improve service levels and meet customer expectations more effectively.

- Sustainability: Reducing waste in production processes contributes to more sustainable manufacturing practices, aligning with corporate social responsibility goals.

These benefits make Demand Flow Technology an attractive option for organizations seeking to enhance their operational efficiency and competitiveness in the market.

Comparing Demand Flow Technology and Traditional Manufacturing Methods

When comparing Demand Flow Technology to traditional manufacturing methods, several key differences emerge. Traditional manufacturing often relies on forecasts to drive production schedules, leading to issues such as excess inventory, longer lead times, and inefficiencies. In contrast, Demand Flow Technology utilizes real-time data to inform production decisions, creating a more agile and responsive manufacturing environment. This shift not only enhances production efficiency but also allows for better alignment with customer demand, ultimately leading to higher levels of customer satisfaction.

The Role of Lean Manufacturing in Demand Flow Systems

Lean manufacturing principles are foundational to Demand Flow Technology. By focusing on eliminating waste and optimizing processes, lean practices support the goals of demand flow systems. Key lean methodologies such as Value Stream Mapping and Continuous Improvement (Kaizen) play a vital role in identifying areas for improvement within demand flow processes. These methodologies help manufacturers streamline their operations, reduce lead times, and enhance overall production efficiency.

Exploring Just-in-Time (JIT) Production Techniques

Just-in-Time (JIT) production is a crucial aspect of Demand Flow Technology. This technique minimizes inventory levels by producing goods only as they are needed in the production process. JIT helps reduce waste, lowers holding costs, and enhances cash flow by aligning production schedules with customer demand. Implementing JIT requires a high level of coordination between suppliers, manufacturers, and customers, ensuring that materials arrive just in time for production without delays. This approach can significantly enhance operational efficiency and responsiveness to market fluctuations.

Understanding Pull Systems in Demand Flow

Pull systems are an integral part of Demand Flow Technology, contrasting with traditional push systems that rely on forecasts. In a pull system, production is initiated by actual customer demand, ensuring that resources are utilized efficiently. This approach helps minimize overproduction and excess inventory, contributing to waste reduction. Pull systems often incorporate methodologies such as Kanban, where visual signals indicate when to produce or reorder materials, further enhancing responsiveness and efficiency in the manufacturing process.

The Impact of Demand Flow on Production Efficiency

Demand Flow Technology significantly impacts production efficiency by streamlining processes and reducing waste. By aligning production with actual demand, organizations can eliminate unnecessary steps and optimize resource allocation. This enhanced efficiency translates to shorter lead times, improved output, and ultimately, greater customer satisfaction. Moreover, as demand fluctuations occur, a demand flow approach allows manufacturers to adapt quickly, ensuring that production remains aligned with market needs.

Strategies for Successful Demand Flow Implementation

Implementing Demand Flow Technology requires a strategic approach to ensure success. Here are several strategies to consider:

- Conduct a Thorough Assessment: Evaluate current processes and identify areas for improvement related to demand flow.

- Invest in Technology: Utilize advanced software and analytics tools to facilitate real-time data collection and analysis.

- Foster a Culture of Collaboration: Encourage cross-departmental communication to ensure alignment between production, sales, and supply chain teams.

- Train Employees: Provide training on demand flow principles and practices to empower employees to contribute to process improvements.

By following these strategies, organizations can effectively transition to a Demand Flow approach and realize its benefits.

Best Practices for Demand Flow Management

To maximize the effectiveness of Demand Flow Technology, organizations should adopt several best practices:

- Emphasize Continuous Improvement: Regularly review processes to identify areas for enhancement and implement changes as necessary.

- Utilize Value Stream Mapping: This tool can help visualize workflows and identify bottlenecks or waste within the system.

- Implement Effective Communication Channels: Ensure that all stakeholders are informed about production schedules, changes in demand, and other relevant information.

- Monitor Key Performance Indicators (KPIs): Regularly assess performance metrics to gauge the effectiveness of demand flow initiatives and make adjustments accordingly.

By integrating these best practices into their operations, organizations can optimize their Demand Flow Management processes.

Overcoming Challenges in Demand Flow Technology

While Demand Flow Technology offers numerous benefits, it also presents challenges that organizations must address. Common challenges include:

- Resistance to Change: Employees accustomed to traditional manufacturing practices may resist adopting new methodologies.

- Complex Supply Chains: Managing relationships with suppliers and ensuring timely deliveries can be challenging in a demand-driven environment.

- Data Management: Collecting, analyzing, and acting on real-time data requires sophisticated systems and processes.

To overcome these challenges, organizations should focus on comprehensive training, fostering a culture of innovation, and leveraging technology to streamline data management.

Demand Flow Systems in Various Industries

Demand Flow Technology is applicable across a wide range of industries, each benefiting uniquely from its implementation. In automotive manufacturing, for example, demand flow systems enable manufacturers to quickly adapt to changing consumer preferences, reducing excess inventory and improving production efficiency. In consumer electronics, where product life cycles are short, aligning production with actual demand helps companies stay competitive. The adaptability of demand flow systems makes them suitable for various sectors, including food and beverage, pharmaceuticals, and textiles.

Tools and Software for Demand Flow Management

Several tools and software solutions facilitate Demand Flow Management, enhancing efficiency and effectiveness. Key tools include:

- Demand Forecasting Software: These solutions analyze historical data to predict future demand accurately.

- Inventory Management Systems: Tools that help track inventory levels in real time, ensuring that production aligns with actual demand.

- ERP Systems: Enterprise Resource Planning (ERP) software integrates various functions across the organization, streamlining communication and data management.

By utilizing these tools, organizations can enhance their Demand Flow Management processes and improve overall operational efficiency.

Analyzing Demand Flow Metrics and Performance Indicators

Monitoring key metrics and performance indicators is essential for assessing the effectiveness of Demand Flow Technology. Critical metrics to track include:

- Cycle Time: The total time taken to complete a production cycle, from start to finish.

- Lead Time: The time taken from receiving a customer order to delivering the finished product.

- Inventory Turnover Rate: This indicates how often inventory is sold and replaced over a specific period, highlighting the efficiency of inventory management.

By analyzing these metrics, organizations can gain insights into their production processes and identify areas for improvement.

The Future of Demand Flow Technology

As industries continue to evolve, the future of Demand Flow Technology looks promising. Innovations in artificial intelligence (AI) and machine learning are anticipated to play pivotal roles in enhancing demand forecasting accuracy and overall supply chain responsiveness. These technologies can analyze vast datasets to identify patterns and trends, allowing organizations to predict customer demand more effectively. This capability is particularly crucial in today’s fast-paced market, where consumer preferences shift rapidly.

Case Studies on Successful Demand Flow Implementation

Analyzing case studies of organizations that have successfully implemented Demand Flow Technology provides valuable insights into best practices and lessons learned. For instance, consider a leading automotive manufacturer that adopted Demand Flow principles to enhance its production efficiency. By implementing a pull-based production system, the company reduced lead times and improved inventory turnover rates. They utilized value stream mapping to identify bottlenecks in their production processes, allowing them to streamline operations significantly.

Another notable example is a global electronics manufacturer that integrated Demand Flow Systems across its supply chain. By adopting real-time analytics and customer demand forecasting, the company successfully reduced production costs while increasing customer satisfaction. The ability to respond quickly to fluctuations in demand enabled them to maintain a lean inventory and reduce waste. These case studies highlight the transformative potential of Demand Flow Technology when effectively implemented.

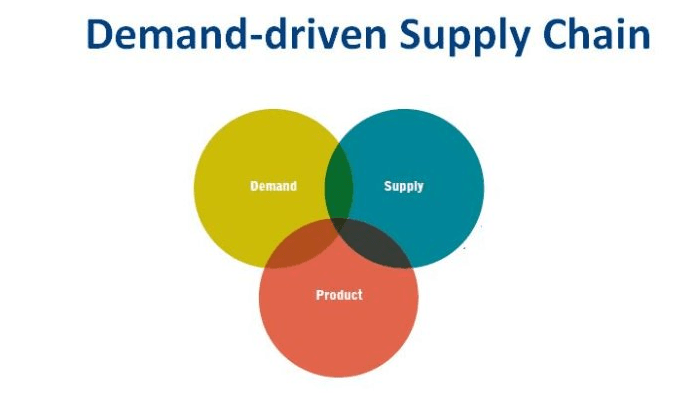

Integrating Demand Flow with Supply Chain Management

Integrating Demand Flow Technology with supply chain management is essential for maximizing its benefits. A demand-driven supply chain allows organizations to align production schedules with actual customer demand, minimizing the risks associated with overproduction and inventory excess. By fostering collaboration among suppliers, manufacturers, and distributors, companies can achieve a more synchronized operation, enhancing overall supply chain efficiency.

For effective integration, organizations must utilize advanced tools and software that facilitate real-time data sharing and communication among all supply chain partners. Technologies such as cloud-based platforms enable seamless access to data, allowing for quick decision-making and adjustments based on market changes. Furthermore, implementing demand forecasting tools can provide valuable insights into customer preferences and market trends, enabling companies to plan their production activities more accurately.

The Importance of Customer Demand Forecasting

Customer demand forecasting is a critical component of Demand Flow Technology. Accurate forecasting helps organizations anticipate customer needs and align their production processes accordingly. By employing advanced statistical methods and analytics, businesses can enhance the accuracy of their demand forecasts, leading to improved inventory management and reduced costs.

Various techniques can be used for effective demand forecasting, including time-series analysis, causal modeling, and machine learning algorithms. Companies should also consider incorporating external factors such as market trends, seasonality, and economic indicators to refine their predictions further. Ultimately, effective demand forecasting empowers organizations to become more responsive to customer needs, enhancing satisfaction and loyalty.

Waste Reduction Techniques in Demand Flow Manufacturing

Waste reduction is a core principle of Demand Flow Manufacturing. By identifying and eliminating non-value-added activities, companies can streamline their operations and improve efficiency. Implementing waste reduction techniques can involve various strategies, including process optimization, employee training, and the use of Lean Manufacturing principles.

Some common waste reduction techniques include:

- Value Stream Mapping: This technique helps organizations visualize their processes, identify waste, and streamline operations by focusing on value-added activities.

- Continuous Improvement: Encouraging a culture of continuous improvement among employees can lead to innovative solutions for waste reduction. Techniques such as Kaizen can help foster this mindset.

- Just-in-Time (JIT) Inventory: By adopting JIT practices, companies can reduce excess inventory and minimize waste associated with overproduction. This approach allows businesses to produce only what is needed when it is needed.

Continuous Flow Manufacturing Explained

Continuous flow manufacturing is a crucial aspect of Demand Flow Technology, characterized by a seamless production process that minimizes interruptions and maximizes efficiency. In this approach, products move continuously through the manufacturing process, reducing waiting times and increasing output.

Key features of continuous flow manufacturing include:

- Standardized Work Processes: Establishing standardized work procedures ensures consistency and quality in production. This consistency is essential for maintaining smooth workflow and reducing variability.

- Automation: The use of automated systems in continuous flow manufacturing can help streamline operations by reducing manual labor and minimizing human error. Automation technologies can include robotics, conveyor systems, and intelligent manufacturing systems.

- Real-time Monitoring: Implementing real-time monitoring systems allows manufacturers to track production performance and identify potential issues before they escalate. This proactive approach contributes to maintaining a continuous flow of production.

Production Flow Optimization Strategies

Optimizing production flow is essential for achieving the benefits of Demand Flow Technology. Several strategies can be employed to enhance production flow, including:

- Process Layout Design: Arranging workstations and equipment in a way that minimizes movement and waiting times can significantly improve production flow. By designing an efficient layout, companies can reduce cycle times and enhance productivity.

- Cross-Training Employees: Training employees to perform multiple tasks can enhance flexibility in the production process. Cross-trained employees can fill in for absent team members, ensuring that production continues smoothly.

- Lean Tools: Implementing Lean tools such as 5S, Kanban, and Visual Management can help improve production flow by reducing waste and enhancing communication among team members.

Role of Automation in Demand Flow Systems

Automation plays a vital role in enhancing the effectiveness of Demand Flow Systems. By integrating automated technologies into manufacturing processes, organizations can achieve higher levels of efficiency, accuracy, and responsiveness. Some key benefits of automation in Demand Flow Systems include:

- Increased Throughput: Automated systems can operate continuously, increasing production throughput and allowing companies to meet customer demand more effectively.

- Enhanced Accuracy: Automation reduces the risk of human error in production processes, leading to improved product quality and consistency.

- Real-time Data Analysis: Automated systems can provide real-time data on production performance, enabling managers to make informed decisions quickly. This data-driven approach contributes to optimizing production processes and improving overall efficiency.

Value Stream Mapping for Demand Flow Efficiency

Value stream mapping (VSM) is a powerful tool for identifying areas of waste and opportunities for improvement in manufacturing processes. By visually representing the flow of materials and information, VSM enables organizations to pinpoint inefficiencies and streamline operations.

The value stream mapping process involves several steps:

- Define the Scope: Identify the specific product or process to be analyzed.

- Map the Current State: Create a visual representation of the current process, including all steps involved from raw materials to finished products.

- Identify Areas for Improvement: Analyze the current state map to identify waste and areas where improvements can be made.

- Develop the Future State Map: Create a vision for the optimized process, highlighting the changes needed to enhance efficiency.

- Implement Changes: Execute the plan for improvement, ensuring that all stakeholders are involved in the process.

Agile Manufacturing and Demand Flow Technology

Agile manufacturing is an approach that emphasizes flexibility and responsiveness to market changes. By incorporating Agile principles into Demand Flow Technology, organizations can enhance their ability to adapt to fluctuating customer demand and rapidly changing market conditions.

Key characteristics of Agile manufacturing include:

- Flexible Production Systems: Implementing modular production systems that can be easily reconfigured to accommodate changes in product design or production volume.

- Collaborative Decision-Making: Encouraging collaboration among teams across the organization to ensure that production decisions are aligned with customer needs and market trends.

- Rapid Prototyping: Utilizing rapid prototyping techniques to quickly develop and test new products, enabling companies to bring innovations to market faster.

Demand-Driven Supply Chain Practices

Demand-driven supply chain practices are essential for effectively implementing Demand Flow Technology. By aligning production and inventory management with actual customer demand, organizations can minimize excess inventory and improve overall supply chain efficiency.

Key components of demand-driven supply chain practices include:

- Collaboration with Suppliers: Working closely with suppliers to ensure that materials are delivered just in time for production, reducing lead times and minimizing inventory costs.

- Data-Driven Decision-Making: Utilizing advanced analytics to forecast demand accurately and make informed decisions regarding production schedules and inventory levels.

- Continuous Improvement: Regularly reviewing and refining supply chain processes to enhance efficiency and responsiveness to customer needs.

Demand Flow Technology and Sustainability in Manufacturing

Sustainability is becoming an increasingly important consideration for manufacturers. Demand Flow Technology can contribute to sustainability efforts by reducing waste, improving resource efficiency, and promoting environmentally friendly practices.

Some ways in which Demand Flow Technology supports sustainability include:

- Minimized Waste: By focusing on continuous flow and eliminating non-value-added activities, companies can significantly reduce waste in their manufacturing processes.

- Resource Efficiency: Implementing Demand Flow principles enables organizations to optimize resource utilization, minimizing energy consumption and reducing their overall environmental footprint.

- Sustainable Sourcing: Companies can collaborate with suppliers to source materials sustainably, ensuring that their supply chains align with environmental and social responsibility standards.

Employee Training for Effective Demand Flow Implementation

Employee training is crucial for the successful implementation of Demand Flow Technology. A well-trained workforce is essential for understanding and applying the principles of Demand Flow, ensuring that all employees are aligned with the organization’s goals.

Key training components include:

- Understanding Demand Flow Principles: Employees should be educated on the fundamental principles of Demand Flow Technology, including its objectives, benefits, and how it fits into the overall production strategy. Training programs should focus on concepts like pull-based systems, continuous flow, and waste reduction.

- Process Familiarization: Hands-on training sessions should be conducted to familiarize employees with the specific processes and technologies used in the Demand Flow system. This includes training on new equipment, software tools, and any changes in workflows that come with implementing Demand Flow practices.

- Lean Manufacturing Techniques: Since Demand Flow is closely associated with Lean principles, training should include techniques such as value stream mapping, 5S methodology, and Kaizen. Employees should understand how these concepts contribute to efficiency and waste reduction within their roles.

- Problem-Solving Skills: Employees should be trained in problem-solving methodologies that empower them to identify issues and implement solutions quickly. Techniques such as root cause analysis and the PDCA (Plan-Do-Check-Act) cycle can be beneficial in fostering a culture of continuous improvement.

- Cross-Training: Encouraging cross-training among employees can enhance flexibility and collaboration within teams. By understanding multiple roles and responsibilities, employees can better support each other and adapt to changing demands in production.

- Real-Time Data Utilization: Employees should learn how to interpret and use real-time data effectively. Training should cover data analytics tools, reporting systems, and how to leverage this information to make informed decisions that align with customer demand.

- Cultural Alignment: Implementing Demand Flow Technology often requires a cultural shift within the organization. Training should emphasize the importance of teamwork, communication, and a customer-centric mindset to create a culture that embraces change and innovation.

- Feedback Mechanisms: Establishing feedback loops within the training program is essential. Employees should be encouraged to share their experiences and suggestions for improvement, which can inform future training initiatives and help refine Demand Flow practices.

Conclusion

As industries continue to adapt to rapidly changing market dynamics, Demand Flow Technology presents a powerful solution for improving operational efficiency and responsiveness to customer needs. By implementing Demand Flow principles, organizations can enhance their production processes, reduce waste, and ultimately deliver greater value to their customers.